GWR '56XX' Class 0-6-2T - 6686

The smaller railway companies which operated in South Wales in the

first two decades of the 19th Century found that the best type of locomotive

for hauling the long trains of coal from pit-head to the docks was the

0-6-2T. When the Great Western

Railway was expanded in 1921 to include these smaller

companies there was a need to introduce a more modern version of the traditional

valleys tank engine. The Chief Mechanical Engineer of the Great

Western

Railway, C. B.

Collett introduced the 56XX Class

in 1924 & over the next 5 years 200 locomotives of the class were

built. Most were built at Swindon, but in 1928, Swindon works was busy & a

batch of locomotives were built at the works of Armstrong Whitworth in

Newcastle-Upon-Tyne. No.6686 was one of this batch, being completed in September

1928. It spent all its life in South Wales, mainly based in Duffryn Yard

Locomotive Shed at Port Talbot & worked on freight & branch passenger

trains in that area. It was withdrawn from service in April 1964.

Most of the locomotives used to

transport coal in South Wales in the early 1920's were of

the

0-6-2 tank design as the Rhymney, Taff & Barry Railways had used this

configuration for some years. After grouping in 1922 & new engines were

required by the GWR, it was decided that this was arrangement was best suited

for the work & the working conditions, & so Charles

Collett designed the '5600' class.

the

0-6-2 tank design as the Rhymney, Taff & Barry Railways had used this

configuration for some years. After grouping in 1922 & new engines were

required by the GWR, it was decided that this was arrangement was best suited

for the work & the working conditions, & so Charles

Collett designed the '5600' class.

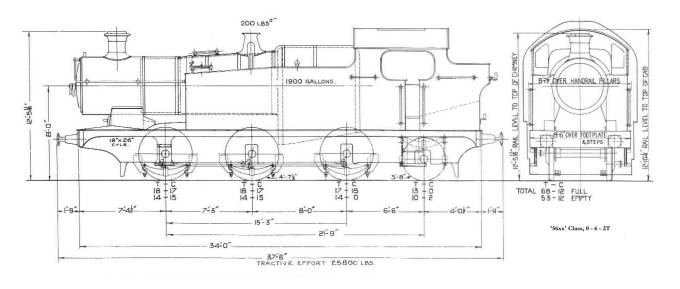

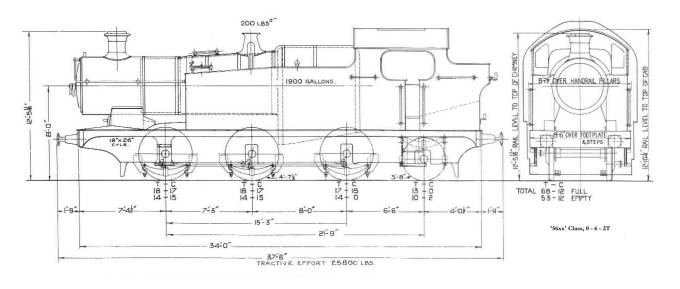

The first engine built was number

5600 - no prototype was needed - & was constructed using many standard Great

Western parts such as Standard number 2 boiler, 4 feet 7½ inch driving wheels &

the 3 feet 8 inch trailing wheel. One striking detail of the class was the

smokebox overhang which ended at the buffer beam.

Production continued with minor

detail alterations, for example parallel buffers replaced the tapered type &

balance weights fitted inside the driving wheels webs opposite the crank pin.

The last batch of the class was built

by Armstrong Whitworth between August & October 1928. One feature of this

class is that they ran better in reverse than in forward gear, making the

trailing wheel into a bogie wheel.

Modification

Some engines built by

Armstrong Whitworth were modified by Swindon for noisy brakes. From 1934, the

class were fitted with recesses in the rear of the bunker, & later on, sliding

screens were fitted to the cab sides.

Withdrawal

The first withdrawals of the

class were four locomotives in May 1962, while the last engine in service was

6668 which survived until the last month of GWR steam, December 1965.

Preservation

Due to these engines working

in Wales, eight of the nine preserved examples were taken to Dai Woodham's yard

at Barry after withdrawal. The nine preserved engines are numbers 5619, 5637,

5643, 5668, 6619, 6634, 6686, 6695 & 6697.

Running numbers: 5600

- 5699, 6600 - 6699.

Built: 1924-7 (5600 - 5699, built by GWR), 1927-8 (6600 -

6649, built by GWR), 1928 (6650 - 6699,

built by Armstrong Whitworth).

|

Specifications |

| Cylinders

|

(2)

18 x 26 inches

|

Driving

wheel diameter

|

4

feet 7½ inches

|

| Trailing

wheel dia

|

3

feet 8 inches

|

Tractive

Effort

|

25,800

pounds

|

| Boiler

type

|

Number

2

|

Boiler

maximum dia.

|

5

feet 0½ inches

|

| Boiler

minimum dia.

|

4

feet 5 1/8 inches

|

Fire

tubes, no. & dia.

|

218

x 1 5/8 inches

|

| Flue

tubes, no. & dia.

|

6

x 5 1/8 inches

|

Superheater

tubes, no. & dia.

|

36

x 1 inch

|

| Boiler

pressure

|

200

lbs/square inch.

|

Boiler

length

|

11

feet 0 inches

|

| Area

of firegrate

|

20.35

square feet

|

Heating

surfaces, tubes

|

1,144.94

square feet

|

| Heating

surfaces, firebox

|

121.8

square feet

|

Heating

surfaces, superheater

|

82.2

square feet

|

In 1987 an initial survey was carried out to assess the

condition with the aim of establishing the priority for restoration. Brief

details of this survey are as follows :-

| Item |

Description of Condition |

| Front tube plate |

Not too bad, may need small areas to be welded |

| Front of boiler |

Good where seen |

| Back of boiler |

Good where seen |

| Copper tube plate |

Several rivets in laps to renew |

| Back tube plate |

Several rivets in laps to renew |

| Copper side plates |

Satisfactory |

| Crown |

Satisfactory |

| Smokebox |

Good |

| Crown Stays |

To be examined after removal of tubes for access to

barrel |

| Stays |

To be examined after removal of tubes for access to

barrel |

| Tubes |

To be renewed |

| Asbestos |

There is a small amount of asbestos in cab |

| Barrel |

Several small patches to be welded |

| Tanks |

Needs patching repairs |

| Bunker |

Needs patching repairs |

the

0-6-2 tank design as the Rhymney, Taff & Barry Railways had used this

configuration for some years. After grouping in 1922 & new engines were

required by the GWR, it was decided that this was arrangement was best suited

for the work & the working conditions, & so Charles

Collett designed the '5600' class.

the

0-6-2 tank design as the Rhymney, Taff & Barry Railways had used this

configuration for some years. After grouping in 1922 & new engines were

required by the GWR, it was decided that this was arrangement was best suited

for the work & the working conditions, & so Charles

Collett designed the '5600' class.